Overview

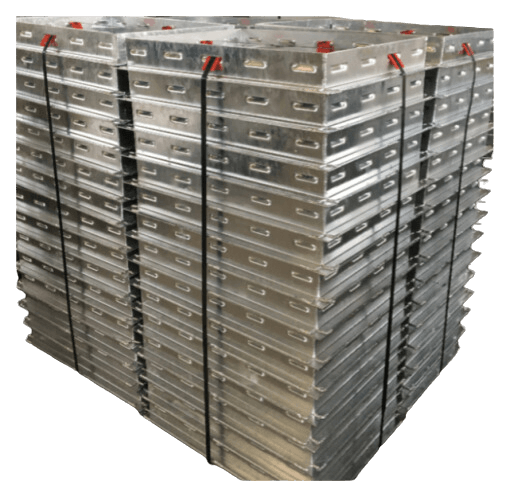

Metalic Vietnam specializes in providing superior corrosion protection for your cover trays and frames with our hot-dipped galvanizing (HDG) services. We expertly coat your fabricated components with a thick layer of zinc, ensuring exceptional durability and long-term resistance against harsh environments. Our commitment to quality HDG processes guarantees a smooth, uniform finish and maximum protection for your metalwork.

Hot-Dipped Galvanizing (HDG) Process

- Pre-Treatment: Cover trays and frames are thoroughly cleaned and prepared for optimal zinc adhesion.

- Fluxing: Components are dipped in a flux solution to remove oxides and promote zinc bonding.

- Hot-Dip Galvanizing: Components are immersed in a bath of molten zinc, forming a thick, protective coating.

- Cooling & Inspection: Galvanized parts are cooled and rigorously inspected to ensure a flawless finish.

Use Cases

- Outdoor Infrastructure: HDG cover trays and frames for manholes, drainage systems, and utility access points.

- Construction & Engineering: Galvanized components for structural elements exposed to the elements.

- Industrial Environments: HDG protection for covers, frames, and other metalwork in corrosive chemical processing plants or factories.

- Marine & Coastal Applications: Exceptional corrosion resistance for covers and frames on docks, boats, and offshore structures.

Metalic Vietnam: Your Partner in Durable Solutions

Maximize the lifespan of your cover trays and frames with our expert hot-dipped galvanizing services. Contact us to discuss your project and experience the benefits of superior corrosion protection.